The CCT series is a coating product developed by Zhong Ang New Material, mainly for sand casting processes of alloy materials such as cast steel and cast iron. The coating series have excellent thixotropy,leveling, coating performance, suspension stability, high aggregate refractoriness, low air generation and good air permeability.

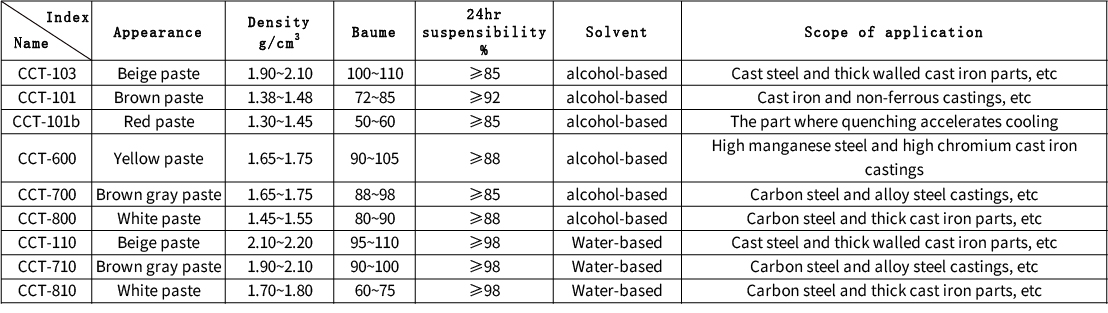

Specification

Product characteristics

1、Excellent thixotropy and leveling;

2、High refractoriness, smooth and dense coating, high strength, ensuring that the roughness of the casting meets the quality requirements;

3、Low air generation reduces defects such as porosity in castings;

4、The automatic peeling of coatings and castings can reduce the workload of casting cleaning.

Method of application

· Select the corresponding coating grade by the casting grade, process, and quality requirements.

· Before use, stirring the coating thoroughly to prevent eddy currents. After adding solvent, it stirring thoroughly and diluted to a Baume degree suitable for the process or coating method requirements. Stirring properly during use.

· When using chilling coatings, after good stirring, evenly coat the areas that require chilling and ignite immediately.

· If the work stopped for more than a day, the coating should be emptied and the coat groove (tank) cleaned before reuse. The remaining coat should be filtered with a 200 mesh or more sieve to remove foreign objects and sand particles. The coating can be used after being screened.

· Under the condition of 0.2-0.3mm coating , each kilogram of water-based and alcohol-based coatings can be coated with 0.7-1.0 square meters.

· Coating method: Brush, soak, or spray.